TXD Steel is a High quality OEM& ODM Metal Steel Material Manufacturer Since 2003.

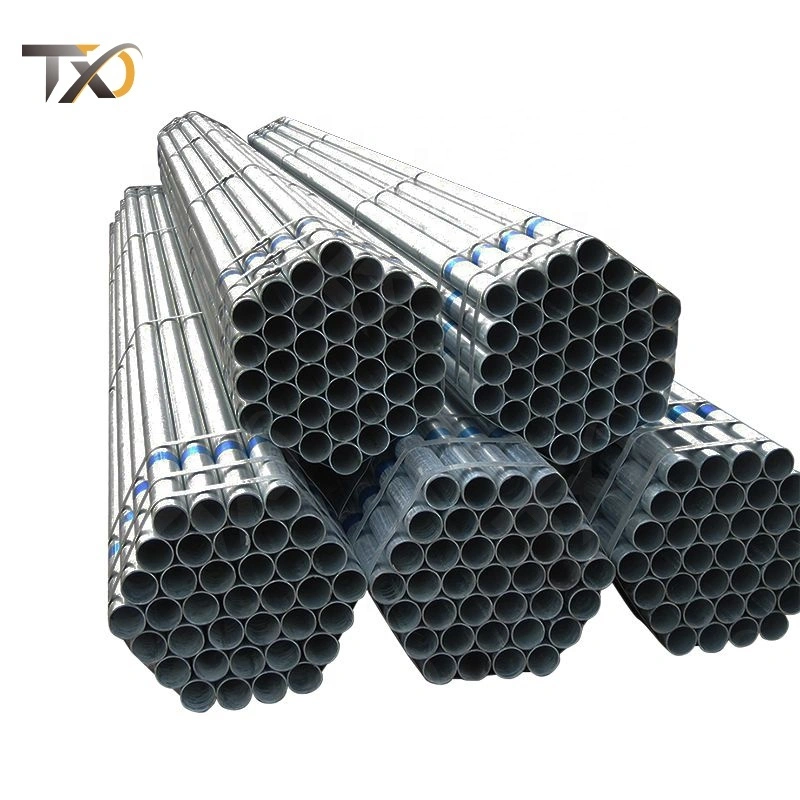

Sch40 Dip Galvanized MS Iron GI Carbon Steel Welded Pipe

In a bustling industrial landscape, where strength meets precision, the "Manufacturers Sch40 Dip Galvanized Ms Iron Gi Mild Carbon Steel Welded Pipe" emerges as a hero—crafted to endure the elements while seamlessly connecting the dreams of builders and architects. Picture a gleaming, rust-resistant surface that not only enhances the aesthetic of every project but also promises years of unwavering performance, standing tall like a sentinel against the test of time. With each sturdy weld, this pipe becomes the silent backbone of robust structures, igniting visions of innovation and durability in the minds of those who dare to dream big.

Smooth surface and solid structure

Experience unmatched durability with our Manufacturers Sch40 Dip Galvanized MS Iron GI Mild Carbon Steel Welded Pipe, designed to withstand harsh environments while maintaining structural integrity. Each pipe comes meticulously packaged to prevent damage during transit, ensuring that you receive high-quality, precision-engineered products tailored to your project needs. With a sleek, smooth finish and robust construction, these pipes are ideal for a variety of applications, providing reliable performance that you can trust.

Corrosion-Resistant Steel

Manufacturers Sch40 Dip Galvanized MS Iron GI Mild Carbon Steel Welded Pipe boasts exceptional durability and corrosion resistance due to its hot-dip galvanization process, ensuring long-lasting performance in various applications. This welded pipe features a standard schedule 40 thickness, providing optimal strength while maintaining lightweight handling for ease of installation. Designed for versatility, it excels in fluid transport, construction, and infrastructure projects, making it an ideal choice for both residential and industrial uses.

Durable

Manufacturers offer Schedule 40 dip galvanized mild steel iron (GI) welded pipes, designed for durability and corrosion resistance. These pipes are ideal for various applications, including construction and infrastructure, thanks to their robust build and reliable performance. With a mild carbon steel composition, they ensure strength and longevity in challenging environments.

Mild Steel

Manufacturers Sch40 Dip Galvanized Ms Iron Gi Mild Carbon Steel Welded Pipe offers exceptional durability and corrosion resistance, ensuring a long lifespan even in harsh environments. This high-quality pipe is crafted from mild carbon steel, providing robust structural integrity for various applications, including construction and plumbing. Key features include an efficient weld design, standardized dimensions for easy integration, and a galvanized coating that protects against rust, making it a reliable choice for both industrial and residential projects.

Application scenario

Manufacturers Sch40 Dip Galvanized MS Iron GI Mild Carbon Steel Welded Pipe is ideal for various construction and industrial applications due to its durability and corrosion resistance. Commonly used in water and gas distribution systems, it provides reliable performance in demanding environments. Its welded design ensures strong joints, making it suitable for both residential and commercial projects.

FAQ

27th Floor, Poly Zhongke Innovation Plaza, Huaiyin District, Jinan City Shandong Province, china.